Precision Turning

Precision Turning

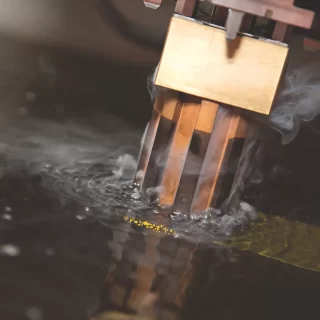

Attica Components are specialists in miniature precision component manufacture. We use a huge range of different techniques, including CNC precision turning to create high quality components to your specifications.

Our precision turning capabilities utilise the latest in fixed and sliding head machining technology to create turned components for industries including medical, electronic, hydraulic, automotive and many more. With decades of experience, industry-leading machinery and a team of fully trained engineers, we deliver on any miniature component projects. Get in touch with us today to find out more.

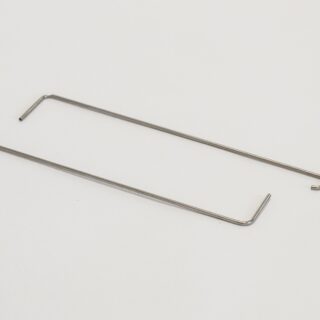

Miniature Turned Parts

Attica has the capacity to manufacture turned parts from 0.5mm in diameter. While components that feature particularly narrow parts relative to their width can deflect in many machining processes.

Our precision turning techniques are state of the art and allow us to create high quality components in a wide range of sizes and materials.

Swiss Style Turning

At Attica Components, we opt for swiss style turning as this provides greater control and accuracy in component manufacture. The key difference between traditional and swiss style is that, in the latter, the component rather than the tool itself is the mobile element.

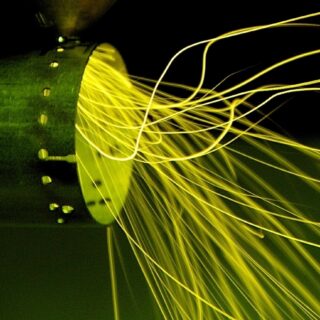

Turning Techniques

There are a wide range of precision turning techniques that Attica can utilise to manufacture your components. Through these, we can produce precision parts to your specifications. As we are specialists in miniature precision component manufacture, we can combine precision turning processes with many of our other offerings to generate multifaceted, complex parts.

Precision turning allows us to create a wide variety of components. With the functionality and detail available from our CNC systems, and the precision of our lathes, turning can produce virtually any shape of component.

Some common features include:

- Holes

- Grooves

- Threads

- Tapers

- Contoured surfaces

- Refining pre-manufactured parts

- Adding rotational elements

Get In Touch

35 Ganton Way

Swindon

SN2 8ES