Laser Welding

Precision Laser Welding

Attica Components is a specialist in the manufacture of miniature components for a wide range of industries. We have an array of capabilities available in order to achieve our high quality of manufacture, including precision laser welding.

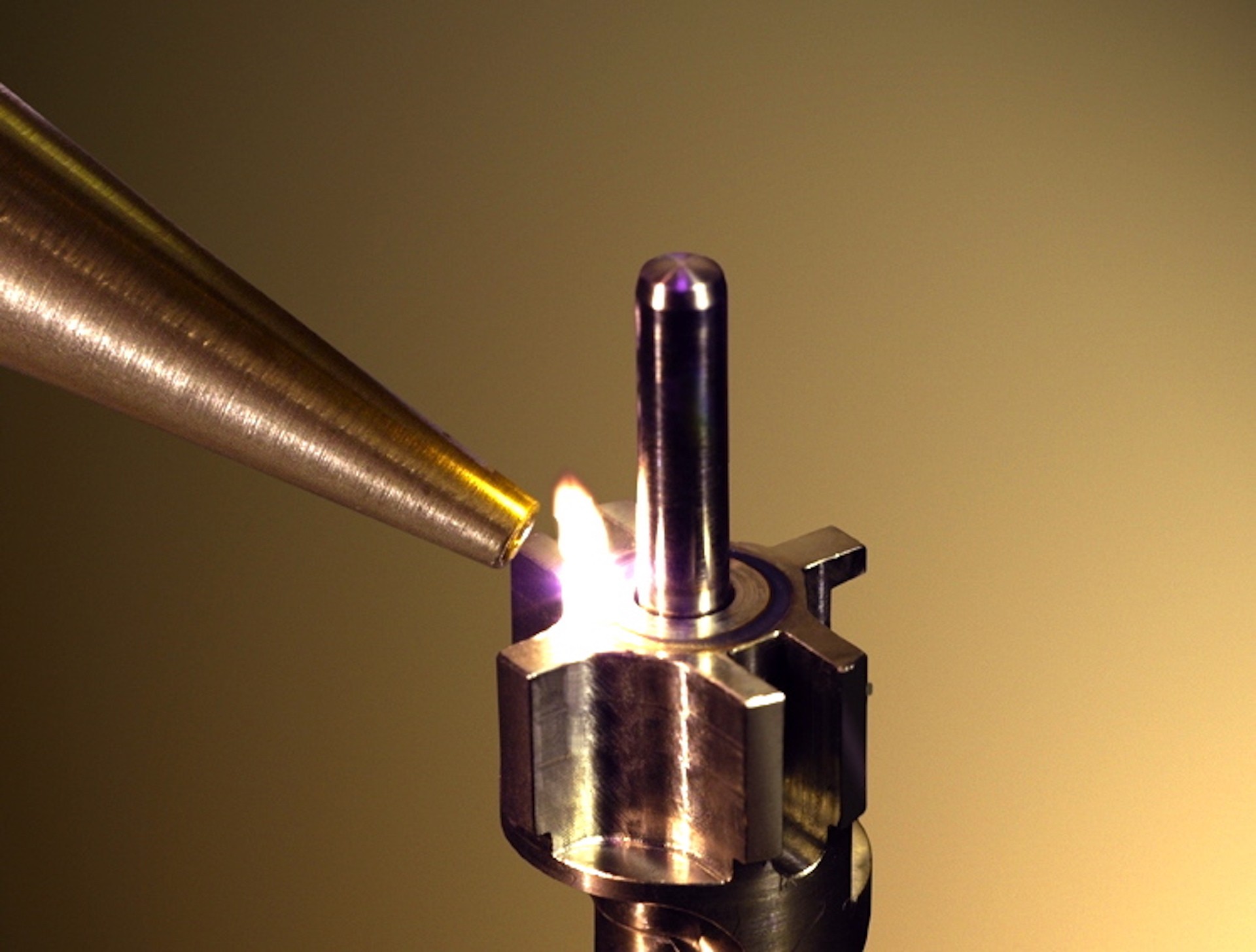

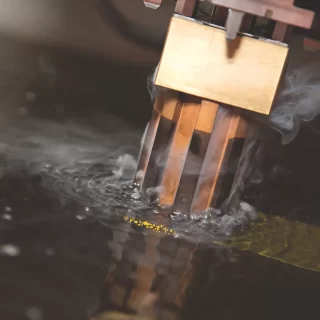

Precision laser welding uses a micro laser beam to produce a focused and intense heat source. This is then used to create a strong, precise weld, joining various miniature metal components or plastics together. On the whole, micro laser welding doesn’t involve a filler material between the two parents components – although one can be used to enhance the strength of the weld.

Our work with micro components means we use laser spot, rotary and laser seam welding, as well as other micro welding techniques, to deliver components to your precise specifications.

Ready to work with a leading engineering partner for quality micro laser welding services? Get in touch today.

Metal Welding

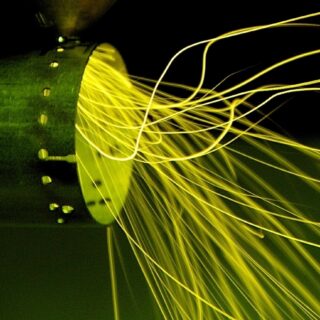

We work with metal laser welding and are able to join stainless steel, nickel alloys, such as Kovar, Monel or Hastelloy, titanium, platinum and other precious metals. If you’re unsure about whether your metal material can be laser welded, simply get in touch!

In addition to laser welding similar materials, we can also weld together different materials. For example, copper wire can be laser welded to stainless steel components, creating a discrete, strong and electrically conductive joint.

How it works

The joint area is shielded with argon to reduce oxidation in the weld area – rather than being placed under a vacuum, as is the case with electron beam welding. Laser welding is therefore a more economic solution when large quantities of similar assemblies require welding.

Precision laser welding doesn’t, on the whole, use a filler or intermediary material between the parent materials. However, a filler can be used to enhance joint strength and viability in some cases. The lack of filler is often a benefit of laser welding over other welding alternatives.

In the medical device industry, for example, the absence of a third material between two surfaces being welded together means only the “parent” materials need to be approved for medical use.

Rotary Laser Welding for Tubes

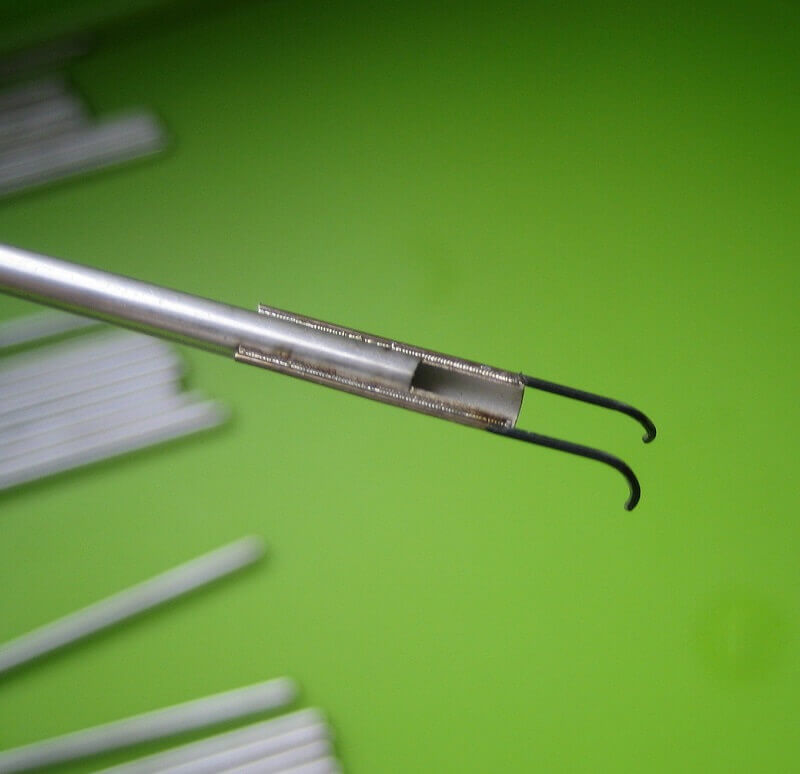

Rotary micro laser welding is one of our precision welding techniques. It’s particularly useful in joining the inside diameter of one precision tube, such as a hypodermic tube, to the outside diameter of a second tube. It’s also used to join circular stamped parts or fine blanked parts.

Medical Precision Laser Welding

We’ve worked with specialists in the medical sector for many years, laser welding materials and components approved for medical application. Find out more about our medical component work.

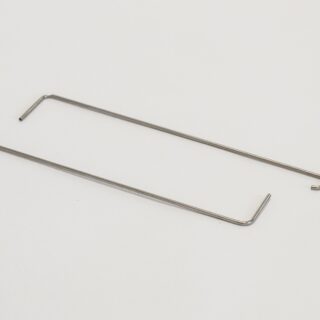

Special needles including biopsy needles can be made by laser welding a precision machined luer, for example, to a hypodermic tube. Other medical devices, such as drug delivery devices, catheters, venous filters and stents, can also be usefully assembled by laser welding. Components made from stainless steel or titanium foil can be laser welded together, for example in the manufacture of heart pacemakers.

We offer precision laser welding services for a range of different applications and components. If you want to find out more, simply get in touch to talk with a member of our team and find out how Attica Components can help you.

Get In Touch

35 Ganton Way

Swindon

SN2 8ES