Tube Cutting

Laser Tube Cutting

Laser tube cutting is one of our popular capabilities as it’s essential in the manufacture of a wide range of precision components such as stents; needles for ophthalmic applications, drug-delivery and special needles; spring forms and more. Attica specialise in the manufacture of miniature precision components and have a wide range of capabilities.

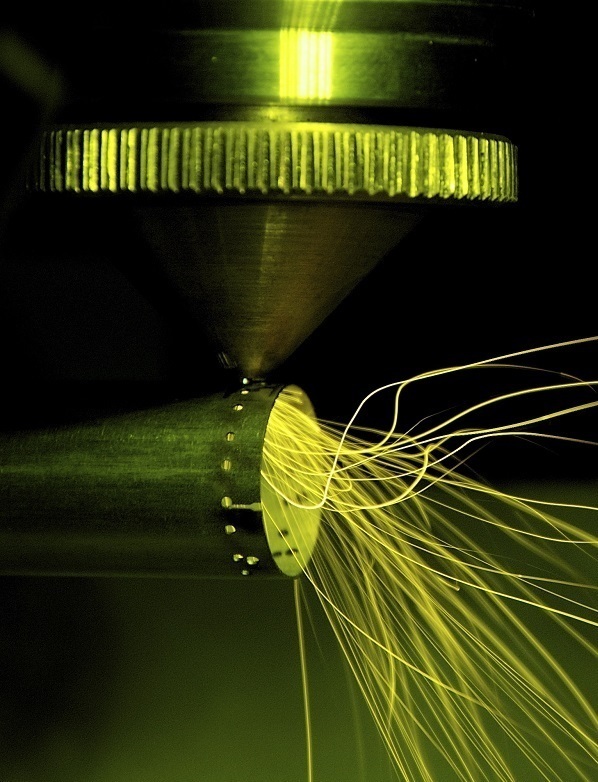

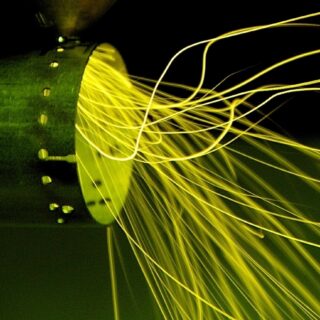

We cut precision stainless steel and nitinol tubes using our Nd-YAG fibre laser. The parallel coherent light from the laser is focused onto a spot approximately 0.02mm in diameter. Metal vaporises within the diameter of this spot, creating a “hole”.

By moving the tube – both rotating it and moving it along X and Y axes – a highly accurate pattern is cut into the wall of the tube. This pattern can consist of holes, slots or can simply mean that the tube is parted off and cut away from the parent component.

Through this method of laser tube cutting, we can make extremely precise components to your specifications.

Get in touch with us today to find out more.

Laser Cut Tubes

Tubes in the range of diameters between 0.4mm and 30mm, and wall thicknesses from 0.1mm to 0.5mm, can be cut. Laser cutting is effective on a range of different materials including stainless steel, nitinol, and other varieties of steel and metal alloys. If you are using a specific material, just get in touch and we’d be happy to discuss capabilities and recommendations.

Examples

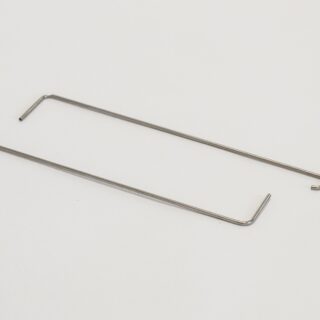

Spring forms can be made by cutting a spiral along the tube. Laser cutting is ideal for this application as the accuracy of the process allows Attica to produce miniature springs to the most precise specifications.

Stents for use in medical devices are commonly made from nitinol (nickel-titanium alloy) using this laser cutting process to produce a burr-free precision-cut. Laser cutting removes a portion of the nitinol tube with precision to allow the metal to flex or expand as needed. An assist gas is used to aid the precision cutting and the removal of molten metal without compromising the quality of the nitinol.

Nitinol laser tube cutting can also be used for orthodontic application, as well as for endographs and filters.

Additional Laser Cutting Services

No Post-Finish Requirements

We have developed specialist, high-frequency pico-second lasers which can cut through metal and ceramic materials without leaving a heat-affected zone. The surface around the cut no longer requires post-finishing, such as pickling or polishing.

Alternative Tube Cutting Methods

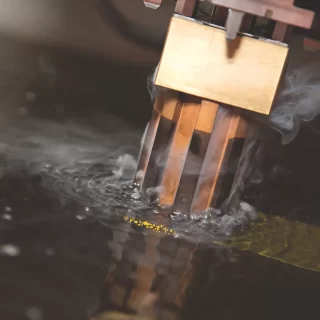

Attica also have alternative tube cutting methods including EDM, or electro-discharge machining.

Advantages of Laser Cutting Tubes

There are alternatives to laser tube cutting, such as abrasive cutting and EDM applications. However, laser cutting has some distinct advantages such as the speed and non-contact nature of the process.

Speed

It’s much more time-effective to use laser cutting than alternative methods. Reducing the time required leads to cost-savings and improved efficiency.

Non-Contact

The non-contact process helps to maintain the purity, strength and viability of important materials.

Precision

Additionally, highly accurate and complex holes and other features can be cut into the tube. With other methods, accuracy and complexity are limited.

We offer precision laser welding services for a range of different applications and components. If you want to find out more, simply get in touch to talk with a member of our team and find out how Attica Components can help you.

Get In Touch

35 Ganton Way

Swindon

SN2 8ES