Aerospace

Aerospace Precision Components

Attica Components are experts in the manufacture of miniature precision components and have over 25 years experience working in the aerospace industry. We have a range of capabilities which allow us to produce high-grade aerospace precision components to your specifications. We can supply parts suitable to both military and civil aircrafts and for use in the most extreme conditions.

Combining the latest technology in CNC machining, laser welding, laser cutting, tube manipulation and more, Attica Components engineers aerospace parts of the best quality. We have a rigorous production process with the highest attention to detail to create the most precise aerospace components with a fast turnaround time.

Ready to work with a first-class engineering partner? Contact Attica Components today.

Reliability. Quality. Precision.

CNC Machining of Aerospace Parts

CNC machining is one of the most frequently used processes in the manufacture of aerospace precision components. We use the latest technology in CNC machining with Swiss-style sliding head lathes able to manufacture parts up to a 20:1 length to width ratio. With fast cycle times and automated second part operations, eliminating the need for manual operators, it’s an extremely efficient and, therefore, cost effective process.

Our CNC machines for Aerospace engineering can handle complex components manufactured from a variety of materials including, but not limited to, steel, stainless steel, aluminium, brass, titanium, copper and more.

Precision Cleaning

We also offer precision cleaning of miniature aerospace components to ensure your parts are delivered as you would expect and you receive the highest quality final product.

Precision Engineering Services

Attica Components have a large scope of capabilities available to manufacture a range of aerospace precision components. Please get in touch to talk to us about your precise requirements.

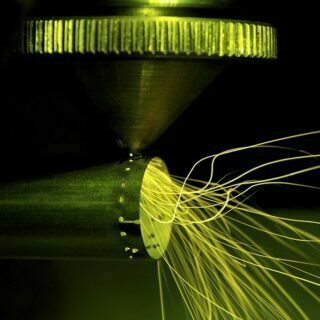

Laser Cutting

We can achieve the highest precious of laser cutting, with the laser able to create holes just 0.02mm in diameter. This allows us to cut intricate patterns and slots to engineer miniature aerospace parts, or simply divide materials into separate parts. We can work with wall thicknesses from 0.1mm to 0.5mm and, for laser tube cutting, tubes in diameters between 0.4mm and 30mm.

Laser Welding

Our precision laser welding capabilities include welding with or without filler. This retains the strength and viability of the original material, ensuring it remains of a high quality grade suitable for aerospace applications. This flexibility is one of the greatest benefits of our method of laser welding. We can also use rotary micro laser welding to join an inner tube to an outer tube and shielding methods to reduce oxidation in the weld area.

Tube Manipulation

Attica has developed our own specialist tooling to swage, flare, bend and cut tubes of various materials including stainless steel, nickel, hastelloy, molybdenum, tungsten, rhenium, monel and precious metals. We engineer tubes for aerospace application with wall diameter thicknesses as low as 0.05mm and up to 30mm. Precision tubes can also be used as crimps, enabling wires to be joined without welding.

Get In Touch

35 Ganton Way

Swindon

SN2 8ES