Quality

Standards of Quality

At Attica we understand that quality, precision and a high level of attention to detail are of extreme importance to our customers and we take great pride in continuously meeting and exceeding our customers expectations. Every aspect of our work is carried out with the highest levels of quality assurance, control and monitoring procedures and we are certified to ISO 9001 standards.

At every stage of each project we work on our team is dedicated to maintaining our high standards, from receipt of raw materials, manufacturing, final inspection and delivery.

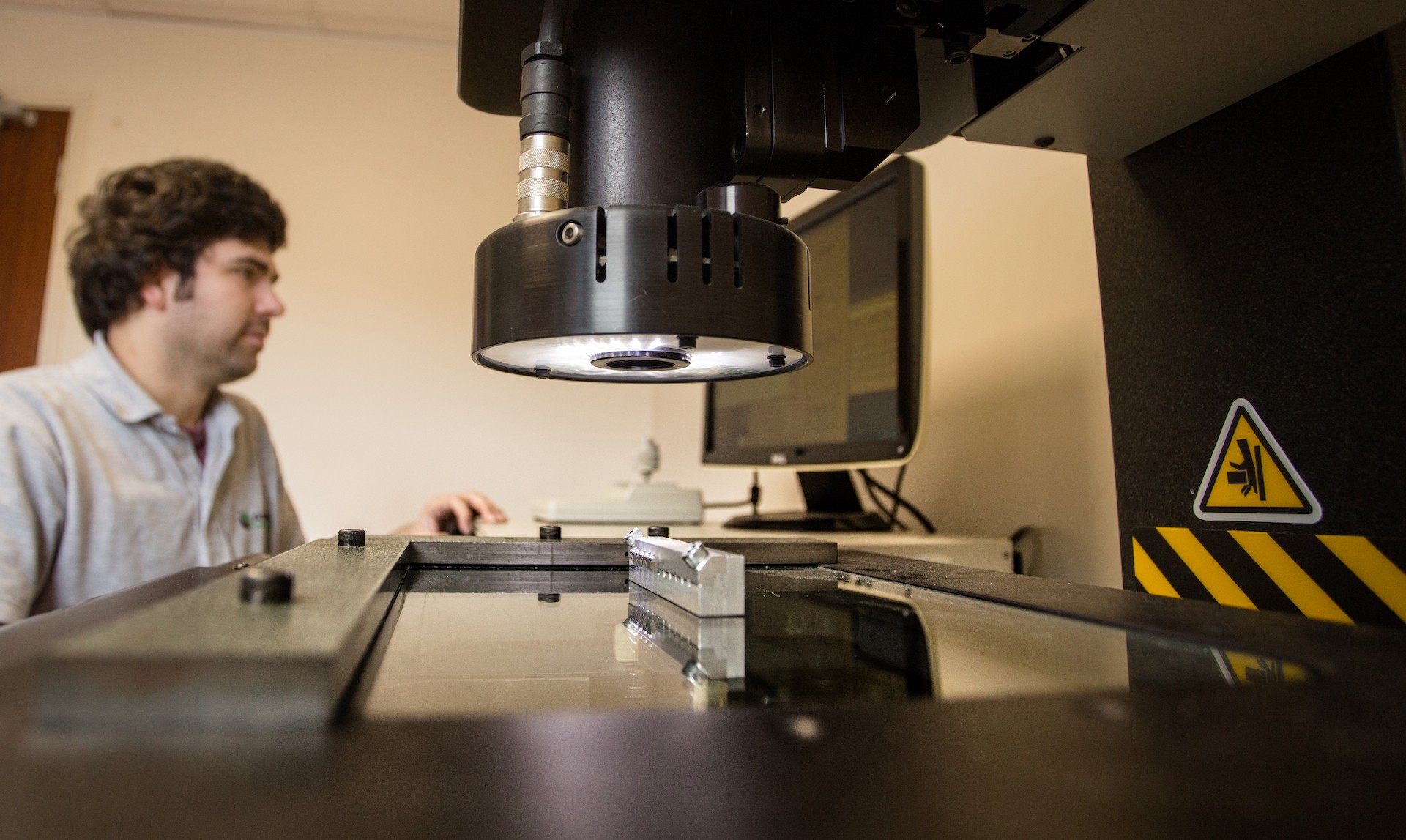

CMM machines are used to inspect the dimensional accuracy of components, ensuring they are within specified tolerances and all of our machines and equipment is regularly inspected, calibrated and maintained to ensure they continuously perform at their best.

We live by the ‘measure twice, cut once’ philosophy to limit defects as well as reduce waste and our impact on the environment. Over the years we have built strong relationships with our customers to develop smooth and efficient processes and working towards cost effective solutions.

If you have any questions or have any specific quality assurance requirements please feel free to get in touch.

Looking for a first class engineering partner?

Get In Touch

35 Ganton Way

Swindon

SN2 8ES